The world of manufacturing has undergone significant transformations over the past few decades. Traditional assembly lines that once relied on human labor and single-task machines have evolved into high-tech environments driven by automation. At the heart of this shift lies one crucial element: the robotics arm.

More advanced, versatile, and intelligent than ever before, modern robotic arms are helping manufacturers adapt to the increasing demands for flexibility, speed, and customization. Let’s explore the key innovations that have revolutionized robot arm design and how these advancements are shaping the future of flexible manufacturing.

The Importance of Flexibility in Modern Manufacturing

As global markets become more competitive, manufacturers are tasked with producing high-quality products while remaining adaptable to fluctuating demands. Flexibility has become a key requirement, allowing manufacturers to switch between products, customize orders, and shorten production cycles.

This shift toward flexible manufacturing aligns with Industry 4.0, the trend of smart automation and data exchange in manufacturing technologies. The modern factory is now an ecosystem of connected systems, where robotic arms play a critical role in improving efficiency and reducing downtime. These arms need to perform a variety of tasks, from welding and painting to intricate assembly, all while being easily reprogrammable. As such, the design of robotic arms has evolved to meet these demands, incorporating cutting-edge technology and materials that enable versatility.

Innovations in Robot Arm Design

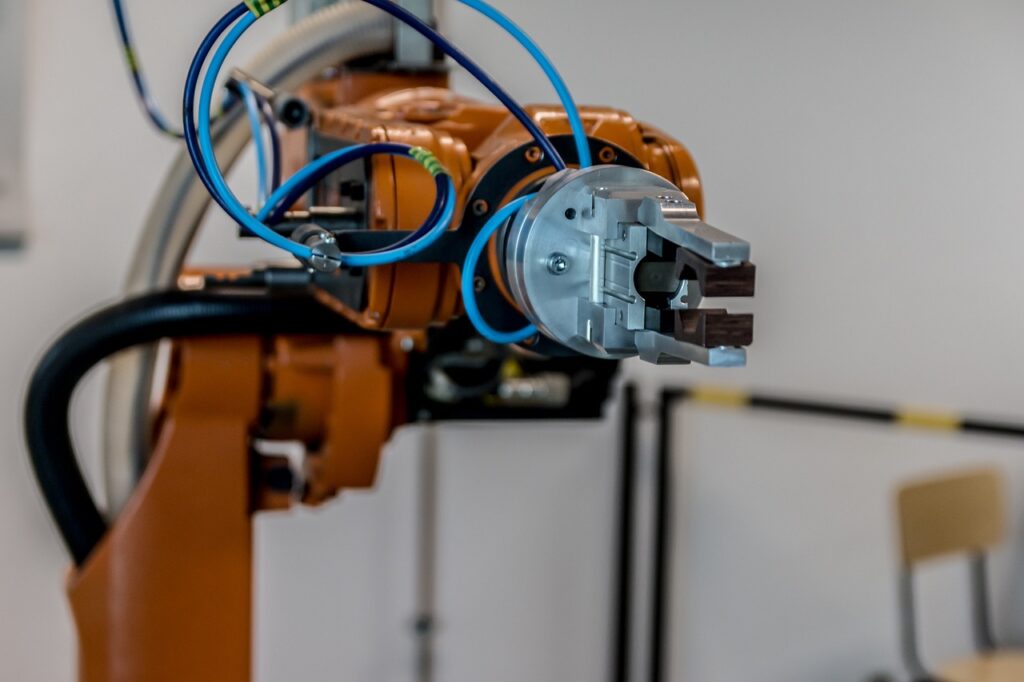

One of the most significant advancements in robotic arm design is modularity. Modular systems allow manufacturers to easily reconfigure robotic arms by switching out components like grippers, sensors, or even the arm segments themselves. This reconfigurable approach provides tremendous flexibility, enabling the robotic arm to adapt to different tasks as needed without requiring a complete system overhaul. For example, a single robotic arm can be equipped to handle welding in one instance and then quickly reconfigured for material handling in the next.

This modularity extends the lifespan of robots and allows manufacturers to scale their operations efficiently. Companies that utilize modular robots are able to respond faster to changes in production demands, ultimately reducing downtime and maximizing output.

Soft Robotics and Adaptive Grippers

Another exciting innovation is the development of soft robotics, which focuses on creating robotic arms and grippers that mimic human dexterity. Soft robots are made from flexible materials, allowing them to handle delicate and irregularly shaped objects without causing damage. These soft grippers are particularly beneficial in industries like food processing, where the handling of fragile products like fruits or baked goods requires a gentle touch.

By employing adaptive grippers, robotic arms are now able to grasp, manipulate, and release objects of varying sizes and shapes. This technology is essential for industries where the product shape or material changes frequently, and rigid robotic arms would struggle to accommodate such variability.

AI-Driven Motion Planning

AI-driven motion planning is one of the most cutting-edge innovations in robotics arm technology. Through AI algorithms, robotic arms can now optimize their paths in real-time, reducing unnecessary movements and energy consumption. AI enables these systems to learn from their environment and make adjustments that improve performance over time.

For example, in automotive assembly, a robot arm equipped with AI-driven motion planning can learn the optimal route to place a component, reducing the overall cycle time. This not only increases efficiency but also reduces wear and tear on the robotic arm itself, ultimately lowering maintenance costs.

Lightweight and Durable Materials

The development of stronger, lighter materials is another area of innovation in robot arm design. Traditionally, robotic arms were built from heavy metals, which limited their speed and agility. However, the introduction of advanced composite materials and lightweight alloys has allowed for faster, more nimble robotic arms without sacrificing strength or durability.

These new materials also improve energy efficiency, as the robotic arms require less power to move. In industries like electronics manufacturing, where precision and speed are crucial, lightweight arms significantly enhance productivity while maintaining the accuracy required for assembling delicate components.

The Role of Sensors and Real-Time Feedback

Advanced sensors are crucial to the evolution of robotic arms. These sensors provide real-time feedback on variables such as force, position, and speed, enabling the robotic arm to adjust its actions on the fly. This feedback loop enhances precision and reduces the likelihood of errors.

Vision systems, including 3D cameras and laser sensors, allow robotic arms to “see” the objects they are working with. This technology is especially important in applications requiring high levels of accuracy, such as assembling small electronic components or inspecting products for defects. Vision-guided robots can now identify and manipulate objects based on their size, shape, and color, adding a layer of intelligence that was previously unavailable in traditional manufacturing systems.

Tactile sensors are another innovation that enhances the capabilities of robotic arms. These sensors give the robot a sense of touch, enabling it to assess the texture and firmness of the objects it is handling. This technology is particularly useful in industries like healthcare, where robotic arms must handle fragile and precise tasks such as assembling medical devices.

Conclusion

The innovations in robotics arm design are paving the way for more flexible, efficient, and intelligent manufacturing systems. From soft robotics and AI-driven motion planning to the integration of advanced sensors and human-centered robot designs, these technological advancements are revolutionizing industries across the board. As manufacturing continues to evolve, robotic arms will undoubtedly remain at the forefront, driving progress and enabling manufacturers to meet the demands of the modern world.